3D-Printing

Description

3D-printing refers to a class of technologies that allow the manufacturing of a wide variety of objects in a completely automatized way through the progressive deposition of multiple layers of material (for this reason it is also known as "additive manufacturing").

Types

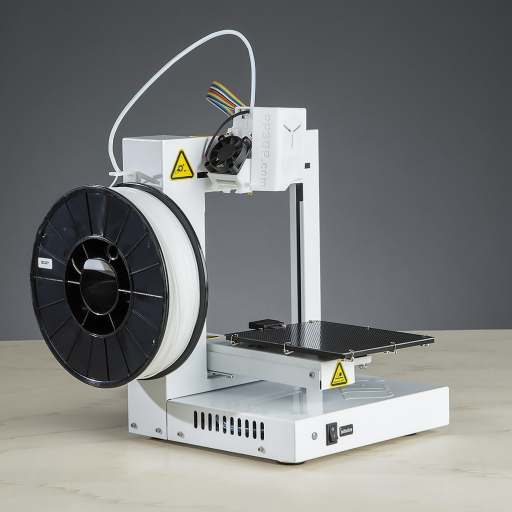

Fused Deposition Modeling (FDM)

The most widely used form of 3D-printing; in FDM a filament of thermoplastic material gets melted by passing through a heated nozzle and deposited unto a board while the nozzle moves to "draw" a layer, and solidifies once it touches the board so that a second layer can be printed upon it, and so on until the entire object is printed. Its functioning is analogous to that of a regular printer, except that instead of ink it uses a filament of thermoplastic material such as ABS or PLA.

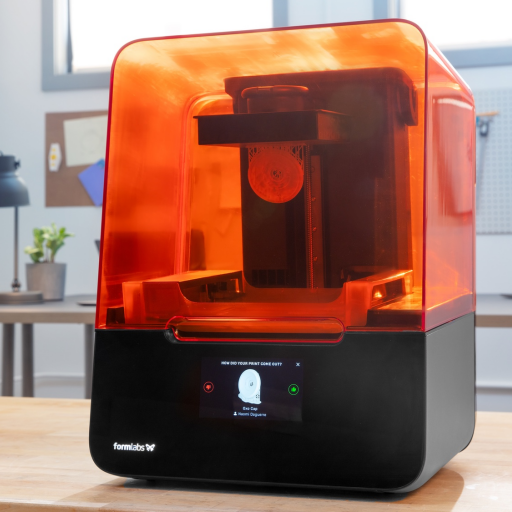

Stereolithography

In stereolithography, the printer models the object through laser-aided polymerization of a liquid resin; a computer-guided laser "draws" the first layer of the object on the surface between a platform and a liquid photopolymeric resin that solidifies exactly where hit, then the platform is dragged up to proceed with the next layer, and so on until the entire object is printed.

Metal Laser Sintering (MLS)

A technique developed specifically for producing metal parts; in MLS stereolithography, a (...) deposits an uniform layer of ultra-fine metal powder, then a high-precision laser "draws" on the layer binding together the target microspheres; the same process is repeated over and over again until the entire object is printed; at last, the remaining unneeded powder is wiped away from the object.

Inkjet Printing (IJP)

IJP is the , the object is formed by spraying progressive layers of minuscule drops of materials that solidify once touching a solid surface; it's almost identical to a regular printer.

Potential

Automation of labor

Thanks to their ability to produce objects in a completely automatized way and to streamline the productive process into 1 single phase, 3D-printers drastically reduce the amount of work required by humans.

All that the user needs to do is to just create or download from the Internet the desired 3D model, transferring it to the printer, and wait for it to be printed.

User-ownership

Thanks to their compact size and ease of use, 3D-printers can be owned and operated by anyone in complete autonomy, without having to rely to external factories or specialized expertise. In other words, 3D-printers allow the users to become producers themselves, which is one of the basic principles of the Self Sustainment System.

Customization power

Because of the aforementioned reason, 3D-printers allow the user to produce entirely personalized goods without having to settle for mass-produced goods produced by corporation, thus granting the maximum degree of personal satisfaction.

Wide versatility

1 single 3D-printer can produce a great variety of goods that are normally produced through various different processes. Different kind of printing materials can be used for different purposes, including flexible materials for soft parts and clothes, and conductive materials for circuit boards and electronic devices.

Self-replicability

The ability to produce parts for other devices, including 3D-printers themselves, makes them excellent candidates to become the Kernel of an S.S.S..

Status

Basic 3D-printers are commercially available for as low as few hundred $ and are able to manufacture a wide variety of objects, including: miniature models, cutlery, furniture, shoes, toys, musical instruments, weapons.

More advanced stuff such as metal parts, high-precision components, multi-material objects and printed circuit boards are also possible, however they require industrial-grade devices who might be worth several thousands $ and be way above the financial capabilities of an average person.

Textiles and microelectronics are currently beyond the capabilities of 3D-printing.

Return